Steel tales: Crafting the Unseen No.5-The third story behind "Wrought"

Wrought iron is a type of iron known for its malleability, ductility, and corrosion resistance. It is created by heating iron then shaping it through processes like hammering or rolling. This iron has a very low carbon content (generally less than 0.08%), which enhances its mechanical properties.

In the past, wrought iron was widely used to make a variety items such as fences, gates, railings, and furniture, valued for its strength and capacity for intricate designs. It differs from cast iron, which has a higher carbon content and is more brittle.

Today, while the production of traditional wrought iron has decreased due to the rise of alternative materials and manufacturing methods, the term may also refer to products made with similar techniques or modern alloys.

Through my research on the history of wrought iron, I learned that ancient Chinese were among the early producers of wrought iron. The Chinese were manufacturing it using the finery forge as early as the 2nd century BC. The earliest known examples of cast iron and pig iron being refined into wrought iron and steel were uncovered at the Tieshengguo site, dating back to the early Han dynasty.

However, wrought iron began to be replaced by mild steel in the late 19th century, primarily after the development of more efficient steel-making processes like the Bessemer process (invented in 1856) and the open-hearth process (introduced in the 1860s). These processes made steel production faster, cheaper, and more consistent in quality compared to wrought iron.

By the early 20th century, mild steel had largely taken over in industries where wrought iron was previously dominant, such as construction, shipbuilding, and manufacturing. Mild steel's superior strength, easier fabrication, and lower cost made it the preferred material for a wide range of structural and industrial applications.

Today, mild steel is ubiquitous in many areas where wrought iron was once used, though wrought iron is still prized for its decorative and historical value. What we call wrought iron these days is mostly the decorative hollow mild steel structures used for fences, gates, railings, and furniture.

I have found a connection between my potential collective work in jewellery and wrought iron, particularly in their decorative qualities, mild steel, and industrial manufacturing. While I could simply embed geometric patterns into my jewellery, I need something more than that. I seek to express my aesthetics and potential as wearable art through this industrially manufactured perforated steel. It’s like trying to find poetry in mundane life to make everything feel special.

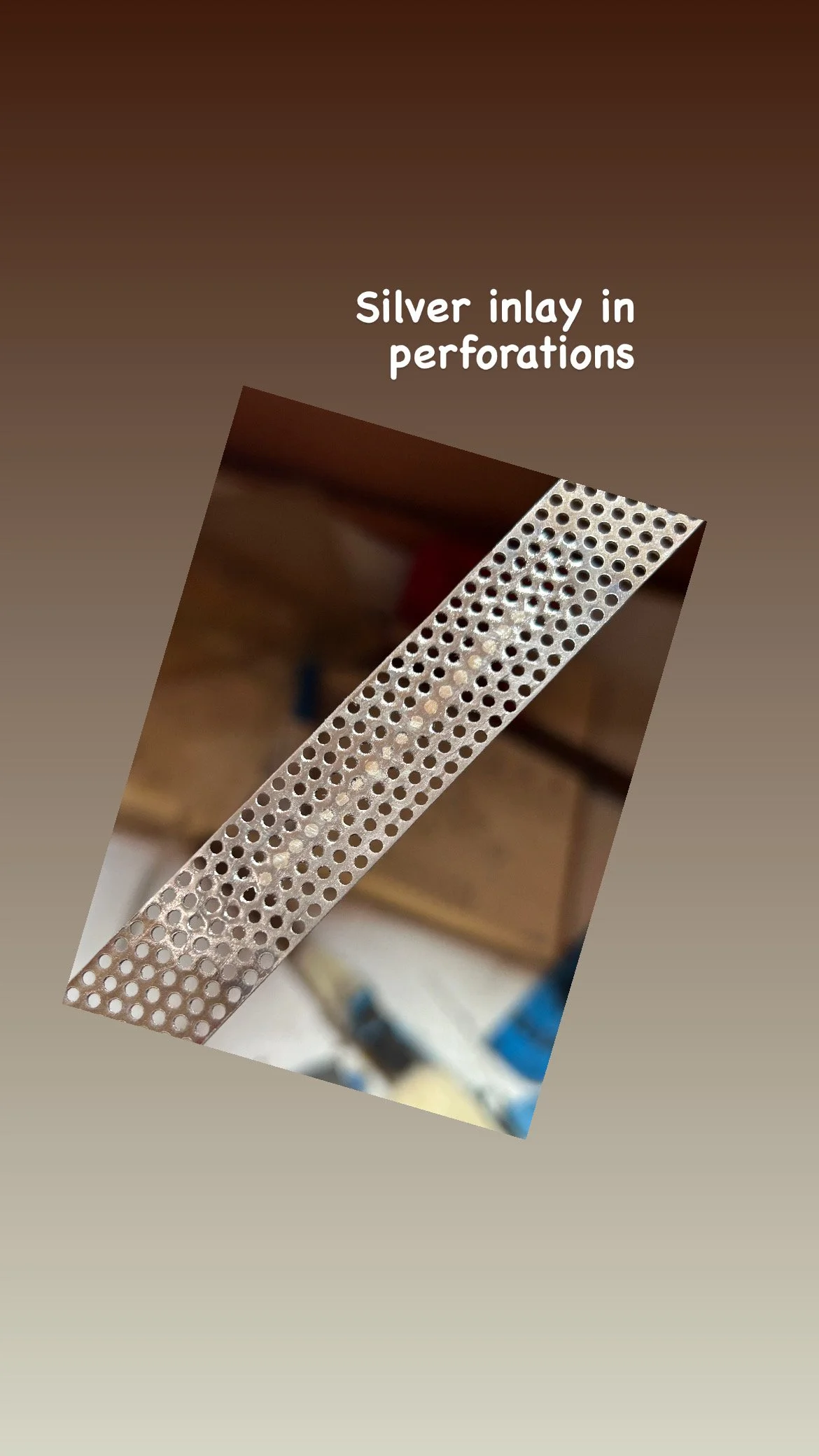

That is how I came across the idea of inlaying silver into the perforations. This approach can maximize my skills in soldering silver and mild steel together, as well as the geometric designs and patterns in my collection. The outcome should be what we call ‘Marriage of Metals,’ a term used to describe the process of soldering contrasting together using a hard solder (at higher temperatures). Typically, copper, brass, and silver are used, but I can create my own combinations for perforated mild steel and silver. After soldering the pieces together, they can be re-cut and soldered in contrasting positions.

Here is my first good attempt to inlay silver into my perforation,.

A wrought iron pattern has been introduced into my inlay.